SMD omarbeidingsmaskin

The Rework Station must be managed of reworking with safety and exactly under that situation.Furthermore, the system operation should be easy and safety to the operator. Our rework Station will be best matching to the needs.

Beskrivelse

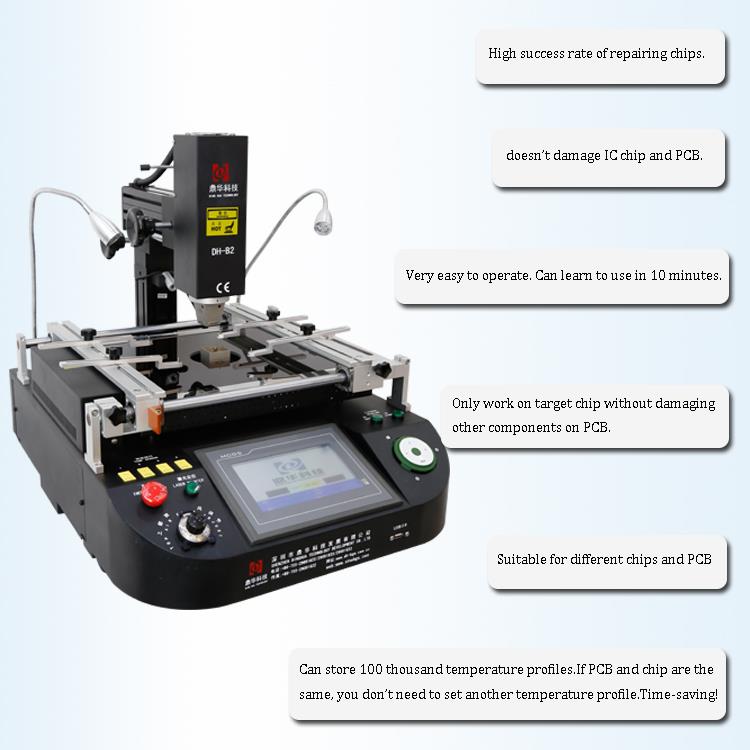

1. Product Features of IRDA keyboard touch screen smd rework station

1.High precision temperature thermocouple can feel the actual temperature precisely.

2. Suction force of the vacuum pump is adjustable, 360 degree rotation in. F. Angle , mounting nozzle is

micro-adjustable.

3. Over-heating protection for the upper hot air heating head.

4. Large ir preheating from the bottom, made of imported heater, will heat the pcb evenly to avoid defo-

5. Equipped with different alloy hot air nozzles (customizable), easy to replace.

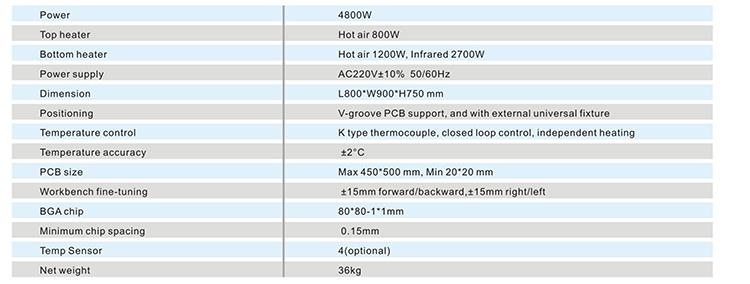

2.Specification of IRDA keyboard touch screen smd rework station

3.Details of IRDA keyboard touch screen smd rework station

1.HD Touch screen interface;

2.Three independent heaters ( hot air & infrared );

3. Vacuum pen;

4.Led headlamp.

4.Why Choose Our IRDA keyboard touch screen smd rework station?

5.Certificate of IRDA keyboard touch screen smd rework station

6.Packing & Shipment of IRDA keyboard touch screen smd rework station

7.Related knowledge

Solder paste must be stored in the refrigerator. The temperature is set to 0~10 degree , and the solder paste

stock is stored in the refrigerator at 0~10 degree ). Use according to the principle of FIFO. (According to the

LOT number or manufacturer of solder paste. Manufacturing date). Guaranteed period of 90 days is used

twice each (10:00 16:00 22:00 4:00) and the temperature curve needs to be done.

environment (22~28 degree ) for 6 hours. Put it in solder paste mixer and stir evenly for 5 minutes, then use it for half

Unopened solder paste after reheating, can be stored below 28 degree for 7 days (Refer to Paste Stirring Specification)

Solder paste PCB should be finished in 100 minutes

Kaifeng's solder paste has not been used for more than 24 hours for end-of-life disposal. When the solder paste

viscosity test. The viscosity value is 320 ~ 392PA.S. Available) and fill in