BGA Package Soldering Repair Reballing Machine

1.BGA Package Soldering Repair Reballing Machine.

2.Most hot selling model in Europe market: DH-A2E.

3.Lifetime after-sales service available.

4.Optics alignment systems and auto feeding systems enabled.

Beskrivelse

Automatic BGA Package Soldering Repair Reballing Machine

1.Product Features of Automatic BGA Package Soldering Repair Reballing Machine

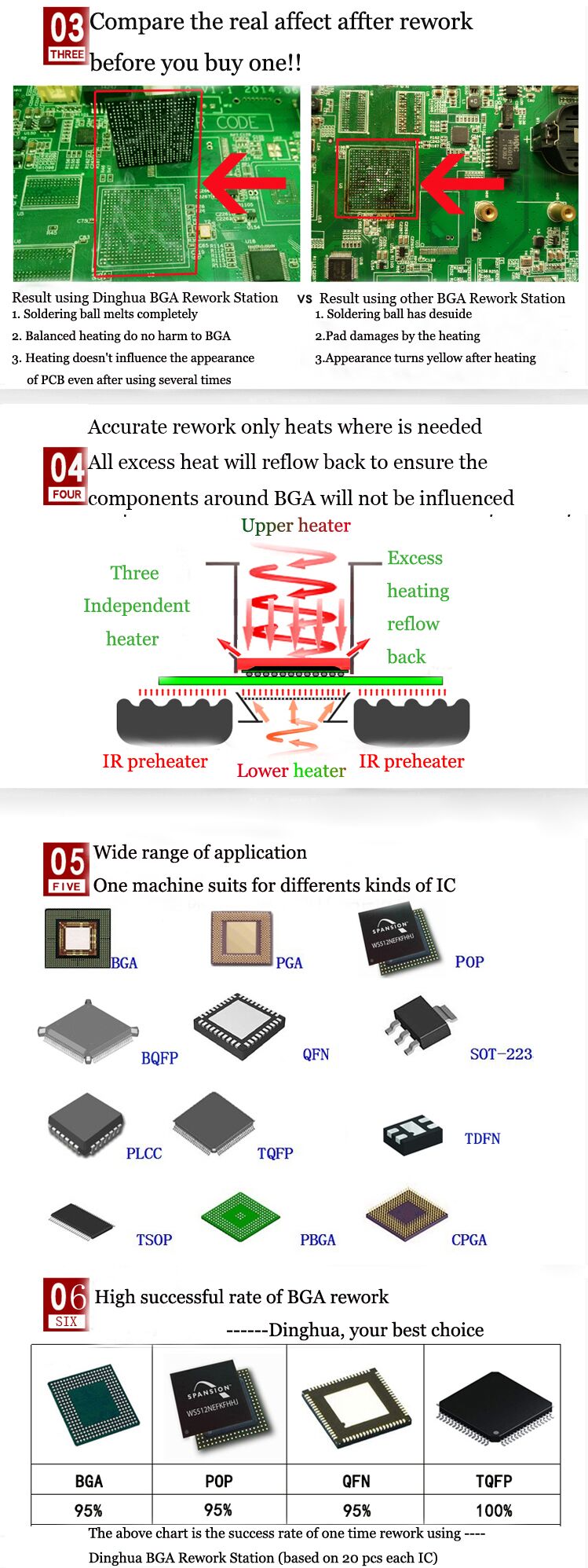

•High successful rate of chip-level repairing. Desoldering, mounting and soldering process is automatic.

• Convenient alignment.

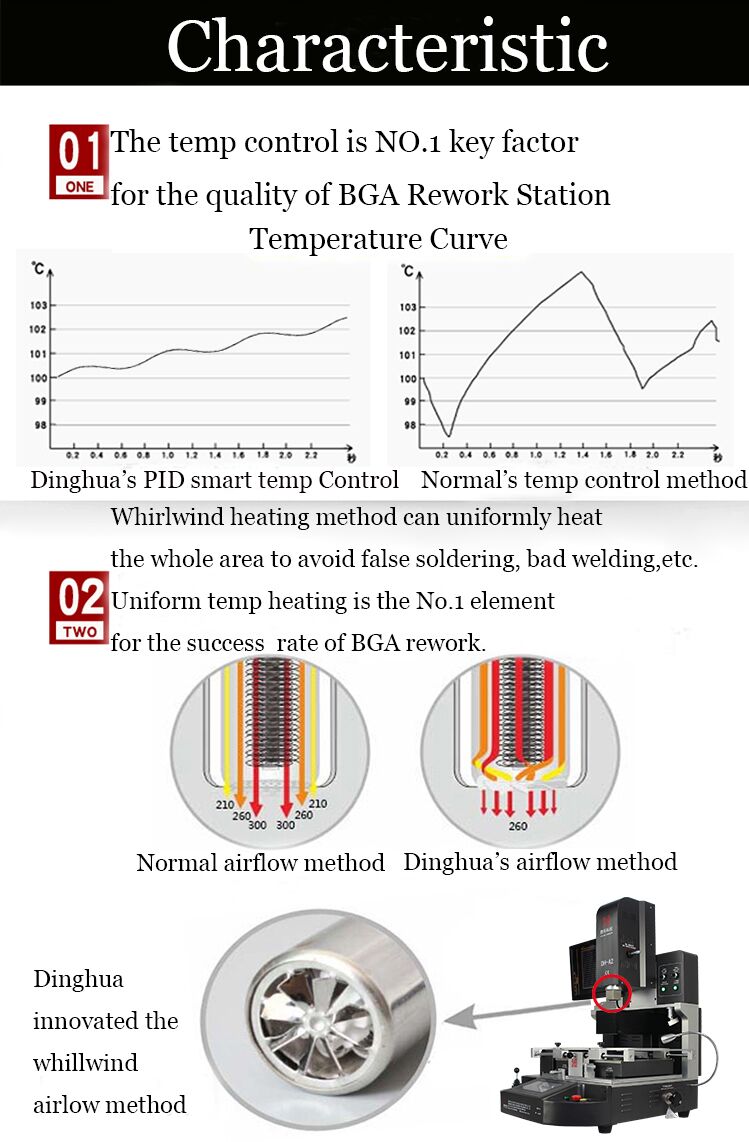

•Three independent temperature heatings + PID self setting adjusted, temperature accuracy will be on ±1°C

•Built in vacuum pump, pick up and place BGA chips.

•Automatic cooling functions.

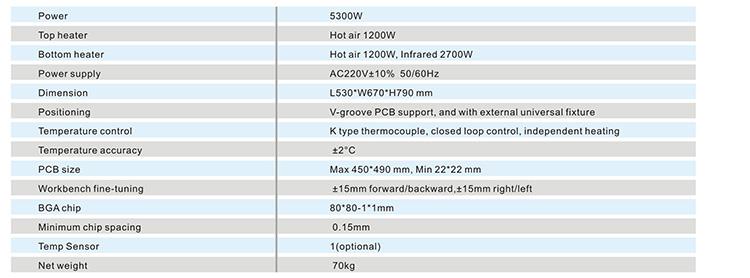

2.Specification of Automated BGA Package Soldering Repair Reballing Machine

3.Details of Hot Air Automatic BGA Package Soldering Repair Reballing Machine

4.Why Choose Our Infrared Automatic BGA Package Soldering Repair Reballing Machine?

5.Certificate of Optical alignment automatic BGA Package Soldering

Repair Reballing Machine

6.Packing list of Optics align CCD Camera BGA Package Soldering Repair

Reballing Machine

7. Shipment of Automatic BGA Package Soldering Repair Reballing Machine Split Vision

We ship the machine via DHL/TNT/UPS/FEDEX, which is fast and safe. If you prefer other terms of shipment, please feel free to tell us.

8. Payment terms.

Bank transfer, Western Union, Credit card.

We will send the machine with 5-10 business after receiving payment.

9. Operation guide for DH-A2E Automatic BGA Package Soldering Repair Reballing Machine

10. Contact us for an instant reply and the best price.

Email: john@dh-kc.com

MOB/WhatsApp/Wechat: +8615768114827

Click the link to add my WhatsApp:

https://api.whatsapp.com/send?phone=8615768114827

10.Related knowledge of Automatic BGA Package Soldering Repair Reballing Machine

What is the standard for slot welding of solderability in the electronics industry of BGA Package Soldering Repair Reballing Machine?

With the comprehensive development and continuous upgrading of the electronic information industry, the application of electronic components

has gradually penetrated into all walks of life of BGA Package Soldering Repair Reballing Machine, but the problem of soldering end oxidation of

electronic components has been plaguing the industry colleagues. This paper starts with the mechanism of oxidation of the soldering end of electronic

components, analyzes the cause of oxidation of the soldering end, and traces the solderability solution of soldering end oxidation according to the reason.

And tried to explore the solderability standard of solder joint oxidation. Keywords: oxidative solderability of electronic components: With the widespread

use of SMT technology in computers, network communications, consumer electronics and automotive electronics, the SMT industry is increasingly clearly

indicating that it will usher in a history of development. On the golden age. At present, although the chip-rate rate of electronic components in China has

exceeded 60%, compared with 90% of the international SMT rate of electronic products, there is still a certain gap. Therefore, it can be said that China's

SMT industry still has a good development space. The healthy development of the SMT industry is inseparable from the common prosperity of the upstream

and downstream sectors of the industry. The SMT production mainly prints the solder paste on the circuit board through the screen printing machine, and

then mounts the electronic components to the corresponding positions of the circuit board by using the placement machine, and then completes the solde-

ring of the PCB chip components through the reflow furnace. In this process, BGA Package Soldering Repair Reballing Machine welding defects such as sol-

dering, offset, solder ball, short circuit, bridging, etc. may be caused by various reasons such as poor screen printing, inaccurate mounting, and improper fur-

nace temperature. This article only oxidizes the solder joints of electronic components. This problem, which plagues the electronic processing industry, is ex-

plored in an in-depth manner, and it is sought to find an effective method for solving the oxidation of the solder joints of electronic components to achieve so-

lderability. Oxidation, as the name implies, is the chemical reaction between the soldered end of the electronic component and the oxygen in the air, which pr-

oduces some metal oxide attached to the surface of the pad, affecting the full contact of the solder, PCB and component parts, and forming an unreliable weld-

ing. At present,BGA Package Soldering Repair Reballing Machine the welding end materials of electronic components on the market are generally metal copp-

er and aluminum, and then plated with Sn/Bi, Sn/Ag, Sn/Cu, etc., almost all electronic components contain metallic copper components. When the external env-

ironment satisfies the conditions of chemical reaction of metallic copper, an oxidation reaction occurs at the soldering end of the electronic component to prod-

uce reddish-brown cuprous oxide (Cu2O equation is: 4Cu+O2=2Cu2O), which is the welding end we often see. The reason for the reddish brown color, someti-

mes we found that the solder end is grayish black, because the cuprous oxide is further oxidized to form black copper oxide (CuO equation is: 2 Cu2O + O2 = 4

CuO), and sometimes We found a green film on the weld end, which is a more serious oxidation reaction. Copper reacts with oxygen (O2), water (H2O) and car-

bon dioxide (CO2) in the air to form basic copper carbonate (Cu2(OH). 2CO3 is also called the copper green equation: 2Cu+O2+CO2+H2O= Cu2(OH)2CO3).

Sometimes we also refer to cuprous oxide as "red copper oxide". Some of the less rigorous times, called cuprous oxide, also known as copper oxide, can be consi-

dered as a generalized copper oxide. This is the basic phenomenon that we usually see in the oxidation of the solder joints of electronic components.

Related products:

Hot air reflow soldering machine

Motherboard repairing machine

SMD micro components solution

LED SMT rework soldering machine

IC replacement machine

BGA chip reballing machine

BGA reball

Soldering desoldering equipment

IC chip removal machine

BGA rework machine

Hot air solder machine

SMD rework station

IC remover device